Part 1

To examine the distribution of camber across the height of a shelf foot panel and to compare 30 degree shelf with 45 degree shelf in that regard, I made four different panels (1000mm x 400mm) from a fairly stiff, 75gsm nylon cloth.

There was no difference between 30 degrees and 45 degrees in the difficulty or otherwise of calculating the width sections of the shelf, if anything 45 degrees was easier. In any case, all arithmetic was done in an instant using an excel spreadsheet. [It is a trivial point, but if there is an "easy one" it would be shelf angle 37 degrees, because you could scale off a 3,4,5 triangle and not need to use trig tables.]

In addition, two panels were made with the barrel round method, as I was expecting to see some contrast. The barrel round method certainly is much easier and quicker than the shelf foot method.

The result was: there was little difference between the shapes of any of them, apart from the actual amounts of camber. The shapes across the height of the panel are all somewhat flat on the sides and bottom, with a "soft chine" transition in roughly the same place - even with the barrel round panels, the shapes were suspiciously "tin plate" looking. I was afraid that the type of cloth might have been a problem, perhaps not representing the real life situation, due to problems scaling down in size.

Second set of tests

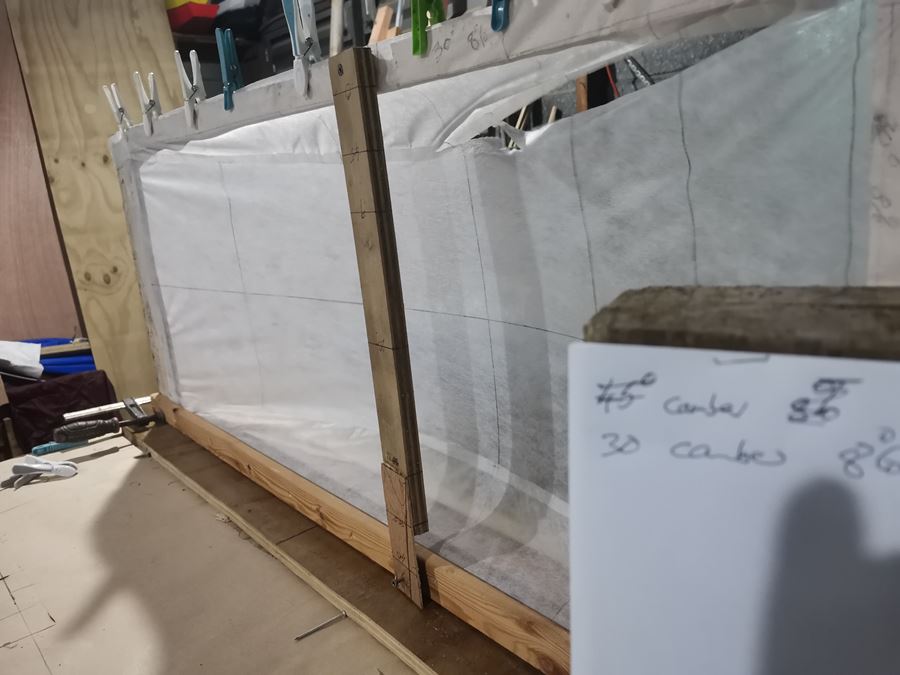

I did the complete experiment all over again, this time making panels from 30 gsm PelTec, an extremely light and soft Tyvec-like material, almost transparent, a bit fiddly to use but hopefully better representing at scale, the typical cloth used in making full size junk sails. There are a few creases and wrinkles – but generally it was easy enough to get the gist of each of the panel shapes.

The aspect ratio of this relatively wide panel is a bit different from that of the normal narrow junk sail panels and this may have affected the camber shapes. (This p/B ratio of 1000/400 more closely resembles the proportions of the Amiina lower mains panels, which is what I am more familiar with).

Three panels (30 degree shelf foot, 45 degree shelf foot and barrel-round were made, with a “designed camber” of 8%. The foil shapes were all mapped from the same identical foil, a simple, relatively sharp entry shape, easy to loft, with max camber at 33.5% of chord.

(The barrel-round camber was not really “designed” – I just used the same foil above, scaled it to a maximum of 45mm and used it for the “rounding”, hoping this would give a camber of about 8%.)

Three more panels were made, identical to above, except the designed camber was this time 10%, and I gave the barrel-rounded panel an extra 10 mm of round.

The panels were inflated and the resulting cambers, as measured, were: for 30 degree shelf: 9% and 10.5%, for 45 degree shelf: 8.6% and 10.5%, and for barrel-round the cambers measured out as: 8.5% and 10%. So, we have two sets of three, with comparable cambers, to compare.

The panels were inflated with a leaf blower (a little bit too directional, but a strong wind force was necessary) and an attempt was made to measure the camber at various points along the height of the panel, from “lower batten” to “upper batten” along a line through the point of maximum camber.

Across the 400mm height, the measurement points (which became X-coordinates” were at: 45mm, 90mm, 200mm, 310mm and 355mm. The measurements of camber at the various points up the height of the panel became the Y- coordinates, and the Y-value at the point “200mm” is in fact the measured maximum camber, mentioned in a previous paragraph.

In order to compare the distribution of camber (as opposed to the amount of camber) the Y values of all of the data sets were scaled so that the maximum camber was 8.5% (for the first data set of three) and 10% (for the second data set).

The results were put back into the excel spreadsheet, which produced the following graphs:

The extreme edges of the panels were too difficult to measure, and the resulting automated “smoothing” of the data is a little odd, so the graphed shapes are slightly different from what the eye could see. The sides of the panels tended to be a little more curved than the flat sides represented here, and where the middle section of a panel rolls into the “soft chine”, those little bumps on some of them are a quirk of the data smoothing algorithm, and may be ignored.

If these graphs look like round plastic wash basins (inverted) then the 30 degree basins will hold a little more water than the 45 degree basins, because the “bottom” is flatter and the “sides” are very slightly closer to vertical, especially at the very outer edges. This amounts to a slightly better distribution of camber across the height of the panel.

The basin shape in the 45 degree10% (the 4th diagram) looks rather like a vertical cross section of the panels on my Serendipity (which were made from a very, very soft nylon approx. 70 gsm – cloth taken from an old well-used spinnaker).

At the extreme outer 3 or 4 cm at the edges, there was no measured data and this distorts the graph a little. In reality the panels tend to be a bit more “horizontal shelf-ish” at the edges than the graphs indicate – as already mentioned. This was more noticeable in the 30 degree shelf and the barrel round panels, and less in the 45 degree panels. The differences were not great, and the middle 80% - 90% of the graphs is a pretty fair representation.

The thing which surprised me most was how closely the cross section of a barrel-round panel resembles the cross section of a 30 degree shelf angle panel. The outlier here is the 45 degree panel, which does seem to distribute camber in a more shapely but perhaps slightly less efficient manner than the other two, though it seemed to me to be slightly easier to inflate.

I did observe, while using this very light and flimsy material, that the panels all seemed to be distributing the forces within the cloth in a rather similar and (to me, unexpected) way. The middle cloth of the shelf foot panels seems to be fully tensioned, leaving the shelf cloths to act more as “gap fillers”. Not entirely – but the shelfs seemed a bit less tensioned than the middle. Indeed, one of the shelf foot panels split along a seam from the gale force of the leaf blower (no stitching was used here, only basting tape) - the middle cloth continued to do the job on its own and the panel did not really change shape.

So, I think the middle cloth is doing a bit more than its share of the work.

Arne refers to the way a barrel-round panel seems to “rob cloth” from elsewhere in the panel in order to take up a smooth shape – this barrel-round method which “should not work but does work”, seems to do the job in a similar way to the shelf foot panels - the middle part of the barrel-round panel does seem to load up and become quite flat, like the shelf foot panels, leaving the outer edges free to turn in that characteristic “soft chine” shape that all of the panels have.

The “soft chine” or transition between the “sides” of the panels and the slightly curved “bottom” does not coincide with the shelf seam, by the way, as it always appears to do in the photographs. That seems to be an optical illusion. The cloth decides where that soft chine occurs – and indeed puts the soft chine pretty much in the same place regardless of where the seam is, and the same soft chine appears there even in a seamless barrel-round panel.

It seems as though maybe the panels all "rob cloth" from the middle in order to take up a fairly universal panel shape, regardless of construction method.

These were things that I thought was a bit interesting.

The raw data is available if anyone wants it.